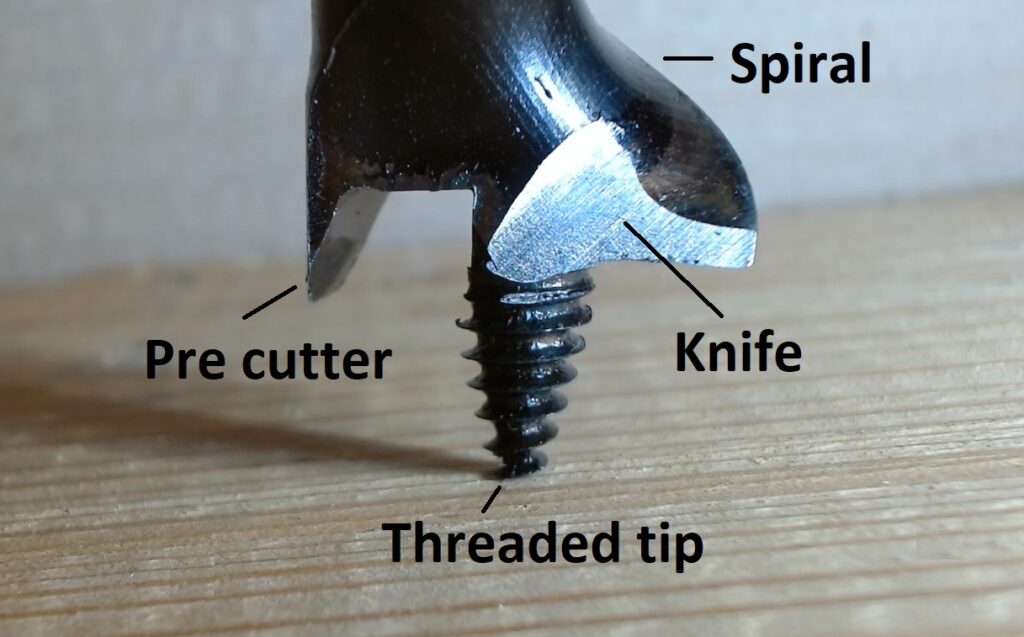

The head of the drill bit is made out of 4 main parts that work in cascade during the drilling process:

1. The threaded tip: will drive the drill bit into the wood. The rotating screw will pull the drill bit into the wood at a speed defined by the pitch of the screw. This pitch varies from 1 mm for small diameters to 2 mm for diameters greater than 30 mm, through 1.5 and 1.75 mm for intermediate

diameters. It is this pitch that will determine the thickness of the chip that will be cut by the knife.

2. The pre-cutter : is the thinnest part (and therefore the most fragile) of the drill bit. When the tip has “engaged” into the wood, the pre-cutter will draw a circle and pre-cut the wood fibers to obtain a hole with well-defined and clean edges (without wood splinters).

3. The knife: acts as a third part to precisely cut the wood chip defined in thickness by the threaded tip and at the edges by the pre-cutter.

4. The spiral: groove know also ad flute, allows the chip and sawdust to be removed to the top. Its role is particularly valuable for long drilling (over 200 mm).

The attached video shows the rest of these operations in detail.

© 2024 Bonnet & Fils – Mentions légales – CGV – Contact